Robot bricklayers set for UK trial amid labour shortages

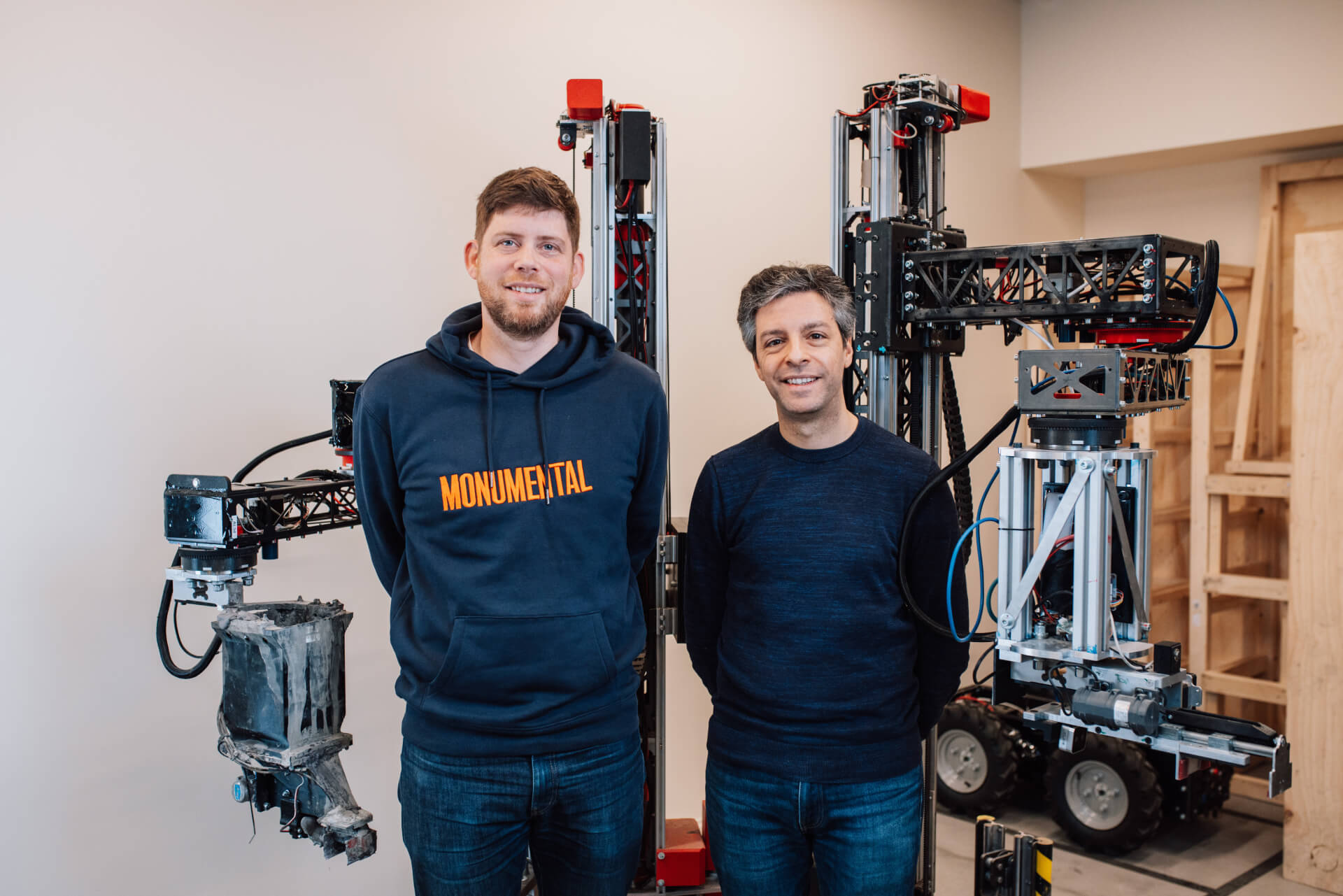

Monumental co-founders Sebastiaan Visser and Salar al Khafaji

Robot bricklayers are set to make their debut on UK construction sites, as the industry continues to grapple with a severe shortage of skilled labour.

The technology, developed by Dutch firm Monumental, features dual-arm robotic systems capable of laying bricks and applying mortar at a pace comparable to human workers. On average, each robot can lay around 500 bricks per eight-hour shift, and the ability to run continuously under supervision.

Monumental’s robots have already been deployed on housing developments across the Netherlands, handling tasks like constructing façades and canal-supporting walls.

Bringing the innovation to British sites, London-based contractor Galostar is preparing to run the UK’s first trials starting next month.

Tony Chapman, managing director at Galostar, said the initial focus will be on adapting the robots to UK building standards and assessing their capability to operate on scaffolding, a key requirement on many domestic and commercial jobs.

“We don’t think they [the machines] will ever completely replace brickies,” Chapman told The Telegraph, “but they can definitely help alleviate the skills shortage we’re dealing with.

“Robots don’t take breaks or time off, so with a few of them, you know exactly what your output will be.”

According to Monumental co-founder Salar al Khafaji, each machine can be managed by a single supervisor, who doesn’t even need to be a qualified bricklayer, reducing the pressure on the already strained labour supply. “You just contract us to do work, and we will come with our machines to do the work, instead of a bunch of humans,” he explained. “Your labour pool will now be much bigger, and you can work multiple shifts.”

The robots are expected to be priced competitively, with rates around £1 per brick, similar to current market rates for manual bricklaying. However, Monumental claims that the robots can also be programmed for complex brick patterns and multi-colour configurations without additional cost, opening the door to architectural detailing that’s often dismissed as too labour-intensive in modern volume housing.

“Today, if you want to ask for a very nice, patterned façade with two brick colours, you’ll get an outrageously expensive quote, because it’s quite hard and it will slow the masons down,” said al Khafaji. “But this is exactly the kind of thing that robots excel at – you just enter it once, and our system allows you to have a mixed supply of coloured bricks and different types of bricks.

“And we won’t charge you more, because it’s not more expensive. So you’ll be able to bring some of those things back into the industry.

“We’re doing a canal wall in Amsterdam soon with really elaborate patterns – bricks sticking out, that sort of thing. It’s kind of crazy, I’m very excited about it.”